AEROSPACE ROBOTIC METAL FINISHING

AEROSPACE & ENERGY SURFACE FINISHING

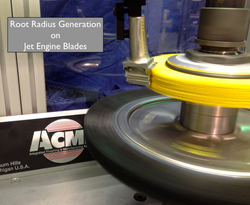

From deburring of turbine engine components to polishing airfoils after milling, Acme robotic finishing systems for the aircraft, power generation, and aerospace industries reduce or eliminate manual labor, lower your unit costs, and achieve new levels of repeatability. ROI can be less than one year.

Processes include (but not limited to):

-

Edge radius and blending

-

Brush deburring

-

Hard tool deburring

-

Flash removal on forged parts

-

Removal and blending of gates and pins

-

Airfoil polishing before and after milling

-

Bright buffing

Components finished on Acme systems include turbine engine components (compression blades and vanes, fan blades, OGV, NGV, and compressor disks), engine shrouds, rotors, cases & housings, blisk disks, and propeller blades.

|  |  |

|---|---|---|

|  |  |

|  |  |

|

ROBOTIC METAL FINISHING VALUE PROPOSAL

-

Acme industry-leading solution in a turn-key solution that also includes:

-

Design, build and integration of the machinery and robots

-

Complete process development with a process "recipe" specific to your production needs and specs

-

Complete programming of the equipment prior to delivery

-

Training both at Acme and your facility

-

Installation Support

-

-

Options for system integration

-

Options for automatic measurement and quality validation

-

Intuitive and comprehensive operator interface

-

Our Systems are designed and built to meet RIA 15.06 safety standards

-

We build to UL or CE mark if required