ROBOTIC METAL FINISHING SOLUTIONS

CORE COMPETENCIES

ac·me the point at which someone or something is best, perfect, or most successful

Acme has been providing quality tools to the metal finishing industry since 1910. This kind of longevity is unparalleled in the industry and has resulted in an industry-leading wealth of knowledge that makes Acme the preferred supplier across a broad spectrum of industries. Acme's has a wide variety of applications within our core solutions that provide our customers with industry leading technology.

ROBOTIC FINISHING INDUSTRIES

Robotic Finishing Cost Savings

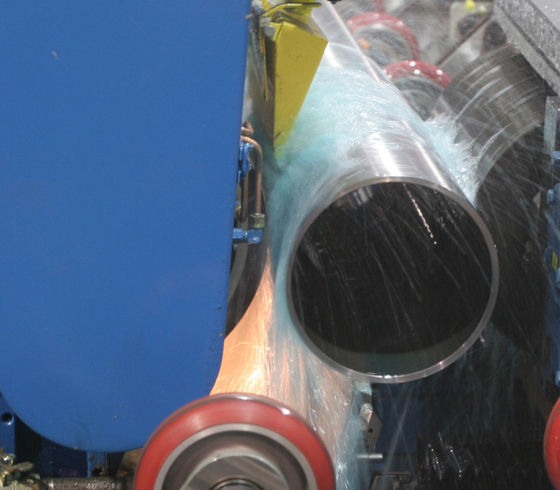

Switching from manual to robotic automation finishing alone can give you three to four times longer media life, as a result of contact efficiency (time on the part), constant work pressure, cycle time repeatability, and part path programming capability. Flexible, automatic force control, with variable-speed spindle motors, optimizes compliance (response and reaction) of the finishing heads to suit the operation.

Off-line programming and simulation (Roboguide) speeds up the program development process and increases utilization of the robotic finishing system. Programs for complex parts and shapes are created and verified quickly. Heat monitoring allows automatic process modification to reduce affects of excess heat.

Universal tooling concepts developed by Acme for firearm applications reduce system design, build and operation costs. All equipment is built to RIA and CE specifications.

Unattended operation, with custom part queuing options, reduces labor content.

Maintenance time and costs are minimized with on-line diagnostics and documentation. Troubleshooting can be performed via modem and/or internet, with Ethernet host support

Robotic Finishing Media Life Management

Automatic media wear compensation software ensures consistent performance throughout the life of belts and buff wheels by adjusting cell process parameters (such as cutting rate and force) to match the performance and lifespan of the media. Media life management software can provide up to five times longer belt life than conventional methods.